Troubleshooting Your AC: The Essential Guide to AC Compressor Relay Testing

Is your air conditioner blowing warm air? A faulty AC compressor relay might be the culprit. This often-overlooked component plays a crucial role in your AC system, and understanding how to check its functionality can save you time and money. This guide will walk you through everything you need to know about AC compressor relay testing, from basic checks to advanced troubleshooting.

The AC compressor relay is a small but mighty electrical switch. Its job is to control the flow of power to the compressor, the heart of your air conditioning system. When you turn on your AC, the relay closes, completing the circuit and allowing electricity to flow to the compressor. This starts the cooling process. However, if the relay is malfunctioning, it can interrupt this process, leading to a non-functional AC unit.

The precise origin of the AC compressor relay is difficult to pinpoint, as it evolved alongside the development of electrical systems and air conditioning technology. However, its importance is undeniable. Without a functioning relay, the compressor cannot receive power, rendering the entire AC system useless. Identifying and addressing relay issues is vital for maintaining a comfortable indoor environment, especially during hot weather.

One of the most common issues related to the AC compressor relay is its tendency to fail due to wear and tear. The constant switching on and off can cause the internal contacts to degrade over time, leading to a faulty connection. Other issues include corrosion, overheating, and damage from power surges. Learning how to check the relay can help you diagnose these problems early on.

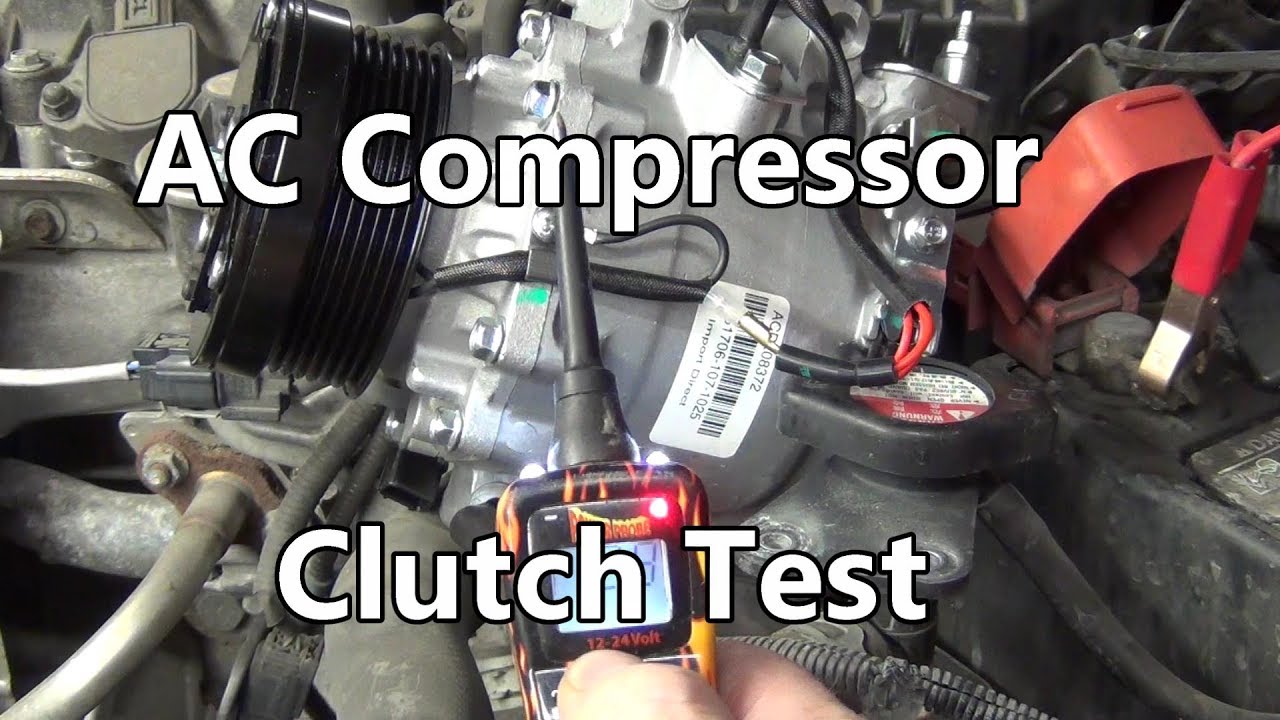

Testing an AC compressor relay involves verifying whether it's effectively switching power to the compressor. Several methods can be used, ranging from simple visual inspections to more advanced multimeter tests. You can visually inspect the relay for any signs of burning, melting, or corrosion. A multimeter can be used to test the relay's continuity and voltage. A clicking sound usually indicates the relay is functioning correctly. However, absence of a click isn’t always indicative of a faulty relay, further testing might be necessary.

Checking your AC compressor relay regularly can offer several advantages. First, it can prevent unexpected AC breakdowns, particularly during hot weather. Second, early diagnosis of a faulty relay can prevent further damage to the compressor, a much more expensive component to replace. Third, being able to troubleshoot relay issues yourself can save you the cost of calling a technician for minor repairs.

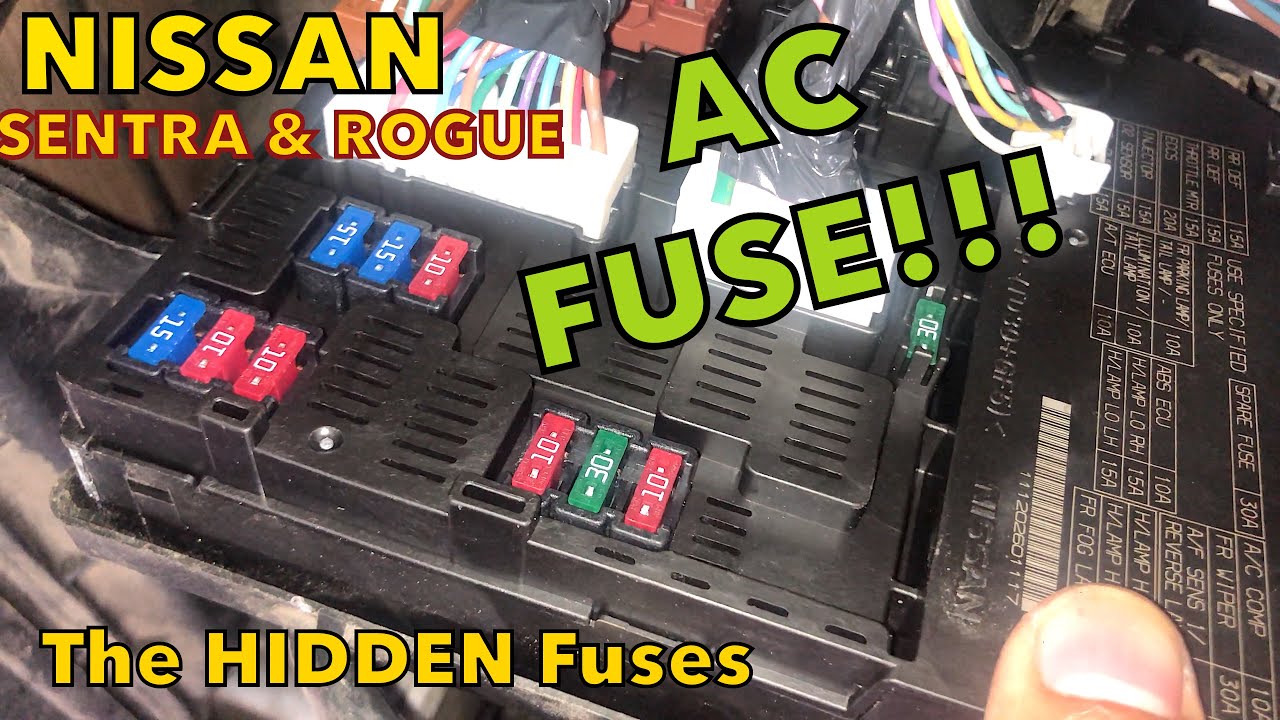

Before beginning to test the AC compressor relay, gather the necessary tools, including a multimeter and potentially a replacement relay. Locate the relay, usually found in the fuse box under the hood or near the AC unit. Consult your vehicle's manual for the exact location. Once located, carefully remove the relay and perform the chosen testing procedure. If faulty, replace it with a new one, ensuring it is the correct type for your AC system.

Advantages and Disadvantages of Testing AC Compressor Relay

| Advantages | Disadvantages |

|---|---|

| Cost savings by avoiding professional repairs for minor issues | Risk of electric shock if not handled carefully |

| Prevents major AC breakdowns | Potential for misdiagnosis if not tested properly |

| Extends the lifespan of the AC system | Requires basic understanding of electrical systems |

Best Practices:

1. Always disconnect the power before handling the relay.

2. Use the correct type of multimeter for accurate readings.

3. Refer to your vehicle's manual for specific instructions.

4. If unsure, seek professional help.

5. Never force the relay into its socket.

Frequently Asked Questions:

1. Q: Where is the AC compressor relay located? A: Typically in the fuse box or near the AC unit. Consult your vehicle's manual.

2. Q: How often should I check the relay? A: It’s a good idea to check it annually or if you suspect AC issues.

3. Q: Can I test the relay without a multimeter? A: A visual inspection can sometimes reveal obvious problems, but a multimeter is recommended for accurate testing.

4. Q: What does a clicking sound mean? A: It usually indicates the relay is functioning correctly.

5. Q: What if the relay isn't clicking? A: Further testing with a multimeter is required.

6. Q: How much does a new relay cost? A: They are relatively inexpensive, usually under $20.

7. Q: Can I replace the relay myself? A: Yes, in most cases, it's a simple replacement.

8. Q: What if the new relay doesn't fix the problem? A: The issue may lie with other components of the AC system. Consult a professional.

Tips and tricks for testing include using alligator clips for easier multimeter connections and having a spare relay on hand to quickly replace a faulty one.

In conclusion, understanding how to evaluate the AC compressor relay is essential for maintaining a functioning AC system. This knowledge empowers you to troubleshoot common AC issues, avoid costly repairs, and prolong the life of your AC unit. By following the outlined steps and best practices, you can confidently diagnose and address relay problems, ensuring a cool and comfortable environment even during the hottest days. Investing a little time in learning these simple testing procedures can pay off significantly in the long run, saving you both time and money. Remember that regular maintenance, including checking your AC compressor relay, is key to a smoothly operating air conditioning system. Don't wait until your AC fails completely – be proactive and take control of your cooling comfort today. If you are uncertain about any step, consult a qualified HVAC technician.

Unlocking comfort the toyota rav4s rear passenger space

Never be stranded again the power of pocket jump starters

Elevate your space with behrs limousine black paint