The Intricate Elegance of Hipot Test Wiring Diagrams

Imagine the subtle hum of electricity, the intricate dance of current flowing through circuits. Ensuring the safety and reliability of these electrical systems is paramount, a task where the often-overlooked hipot test wiring diagram takes center stage. It’s a blueprint, a guide, a silent guardian ensuring that the power that fuels our modern world remains contained and controlled.

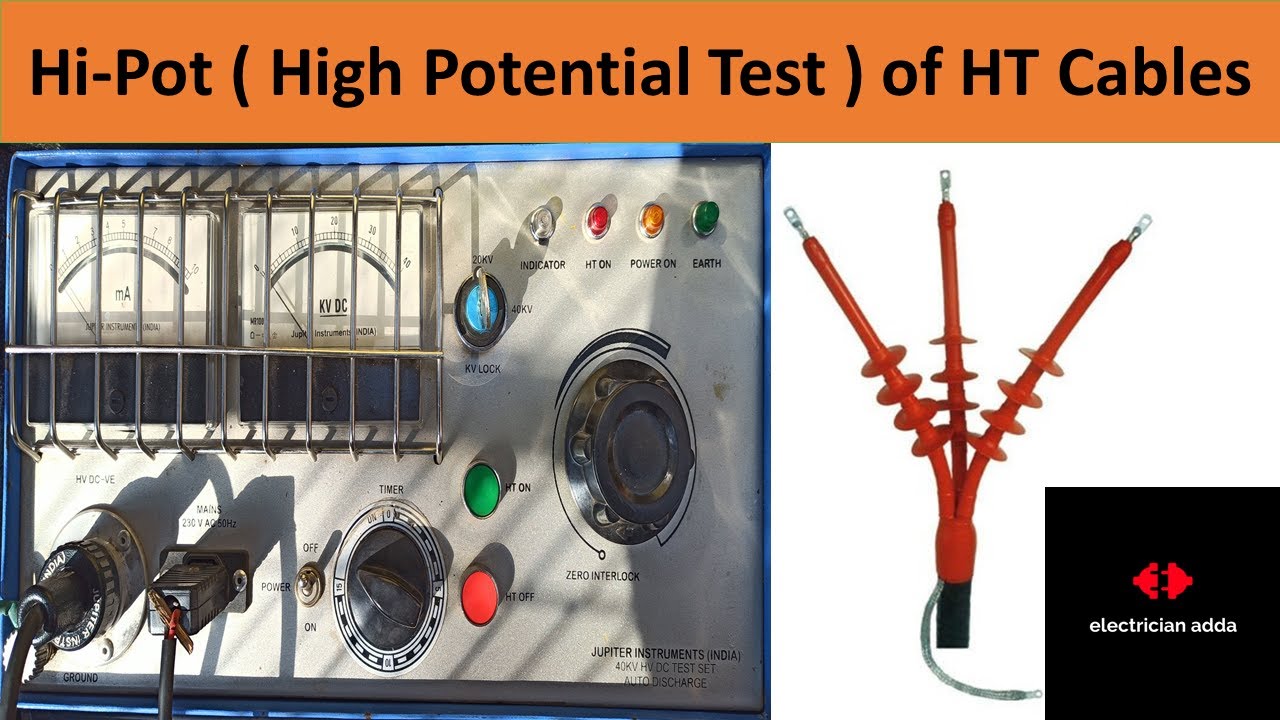

The hipot test, short for high potential (high voltage) test, is a critical process in electrical safety testing. It subjects insulation to a higher-than-normal voltage to verify its integrity. The associated wiring diagram is the sartorial detail, the carefully considered element that orchestrates this powerful performance. It dictates the precise connections, ensuring the test is accurate and effective, revealing potential weaknesses before they become hazardous flaws.

Hipot test wiring diagrams are not mere sketches; they are narratives of electrical flow. They depict the path of the high voltage, highlighting the critical points where insulation integrity is paramount. Understanding these diagrams is akin to deciphering the language of electricity, a skill essential for anyone working with electrical systems or equipment.

The origins of hipot testing are rooted in the growing awareness of electrical safety in the early 20th century. As electrical systems became more complex and ubiquitous, the need for rigorous testing became increasingly apparent. The development of the hipot test, along with its accompanying wiring diagrams, marked a significant step forward in mitigating electrical hazards.

The importance of a meticulously crafted hipot test setup cannot be overstated. A flawed diagram can lead to inaccurate results, potentially overlooking dangerous insulation weaknesses. A properly configured diagram, on the other hand, provides a clear roadmap for conducting the test, ensuring that the insulation is thoroughly evaluated and that potential risks are identified and addressed.

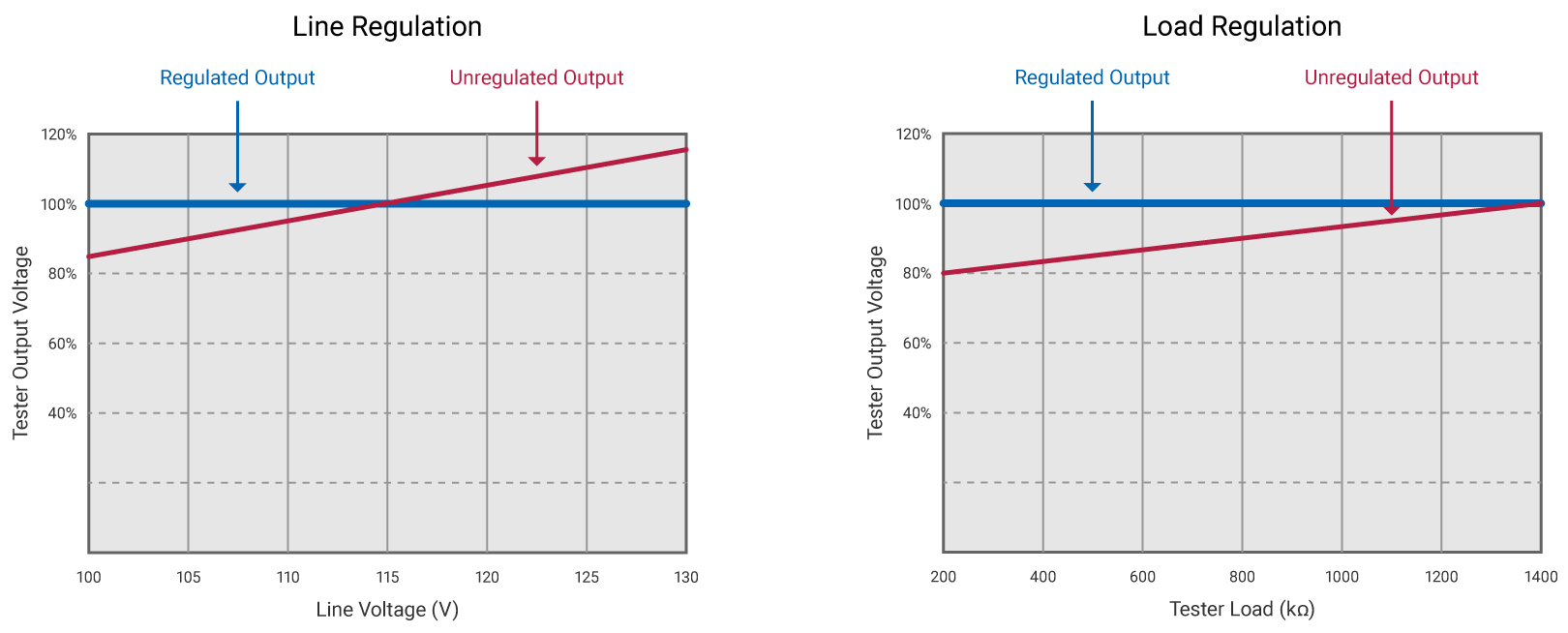

A hipot test wiring diagram typically depicts the connections between the hipot tester, the device under test (DUT), and any necessary safety equipment. It specifies the voltage to be applied, the duration of the test, and the grounding points. For example, a simple diagram might show a hipot tester connected to the input and output wires of a power supply, with the chassis of the power supply grounded.

Benefits of using a well-designed hipot test wiring diagram include: enhanced safety by identifying insulation weaknesses before they cause harm; improved product reliability by ensuring the integrity of electrical insulation; and compliance with safety regulations by providing documented evidence of testing.

Creating an effective hipot test wiring diagram involves several key steps: identify the DUT and its electrical characteristics; determine the appropriate test voltage and duration; select the correct hipot tester and safety equipment; draw the diagram, clearly labeling all connections and parameters; and review the diagram to ensure accuracy and completeness. A successful example might involve testing the insulation of a motor winding, ensuring it can withstand the specified voltage without breakdown.

A basic checklist for hipot testing would include: verify the DUT is disconnected from power; check the calibration of the hipot tester; inspect the test leads for damage; ensure proper grounding; follow the wiring diagram precisely; and record the test results.

Advantages and Disadvantages of Standardized Hipot Test Wiring Diagrams

| Advantages | Disadvantages |

|---|---|

| Improved consistency and repeatability of testing. | May not be suitable for all types of DUTs. |

| Reduced risk of errors due to misinterpretation of diagrams. | Can be time-consuming to develop initially. |

| Facilitates training and knowledge sharing. | Requires regular review and updates. |

Best practices for hipot testing include using appropriate safety precautions, such as wearing insulating gloves and eye protection; ensuring proper grounding of the DUT and the test equipment; using calibrated test equipment; following the manufacturer's instructions for the DUT and the hipot tester; and documenting the test results thoroughly.

Challenges in hipot testing can include difficulties in accessing test points on complex DUTs, dealing with high voltage safely, and interpreting test results accurately. Solutions may involve using specialized test probes, implementing robust safety protocols, and seeking expert advice on data analysis.

FAQs about hipot testing cover topics such as the purpose of the test, the appropriate test voltage and duration, the types of equipment used, safety precautions, and interpreting test results. Tips and tricks for hipot testing include carefully checking all connections, ensuring proper grounding, and documenting all test parameters.

In conclusion, the hipot test wiring diagram, while seemingly a small detail, plays a vital role in the world of electrical safety. It's a testament to the meticulous care and attention to detail required to ensure the reliable and safe operation of electrical systems. Understanding and correctly implementing these diagrams is crucial for mitigating risks, ensuring product reliability, and maintaining compliance with safety regulations. Embracing the intricacies of hipot testing and its associated wiring diagrams is not just a best practice; it’s a fundamental step towards a safer, more reliable electrical future. By understanding the nuances of this process, we contribute to a world powered by confidence, a world where electricity serves us safely and reliably. Take the time to master the art of the hipot test wiring diagram, and you invest in a future where electrical safety is not an afterthought, but an integral part of the design, from the blueprint to the finished product.

Unraveling the mystery the night watch painter

Decoding that mysterious noise a comprehensive guide

Unlocking the shadows a deep dive into the dd 5e rogue