Perfecting Precision Rotating Machinery with Shaft Alignment

Ever wondered how those massive industrial machines run so smoothly? A key factor lies in something you might not expect: precise shaft alignment. Without the proper alignment of rotating shafts, machines can suffer from excessive vibration, premature wear, and costly breakdowns. This is where a shaft alignment tool kit becomes absolutely indispensable. It's like the magic wand for ensuring optimal performance and longevity of your valuable equipment.

Think of a bicycle chain. If it's not properly aligned, it can cause the bike to wobble, wear out quickly, and even break. The same principle applies to rotating machinery in industrial settings, but on a much larger and more complex scale. A shaft alignment tool kit provides the necessary instruments to achieve this critical accuracy.

These kits have evolved significantly over time. Early methods of shaft alignment involved rudimentary tools and a lot of guesswork. Today's advanced kits utilize laser technology and sophisticated software to provide incredibly precise measurements and guidance. This evolution mirrors the increasing complexity and demands of modern industrial machinery.

The importance of proper shaft alignment cannot be overstated. Misalignment is a leading cause of machinery failure, which can result in significant downtime and repair costs. A shaft alignment tool kit is an investment that pays for itself many times over by preventing these costly issues and ensuring smooth, efficient operation.

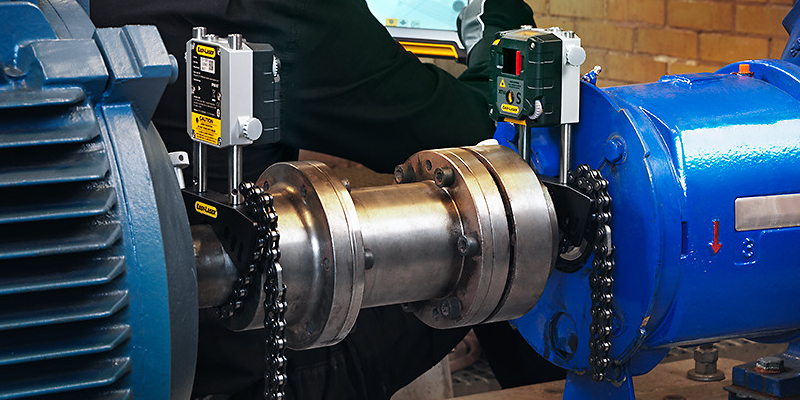

A comprehensive shaft alignment tool kit typically includes laser transmitters and receivers, magnetic mounting brackets, and a display unit. The transmitters project laser beams onto the receivers, and the display unit analyzes the beam deviations to determine the degree of misalignment. The kit then guides the user through the necessary adjustments to achieve perfect alignment.

Historically, shaft alignment was a time-consuming and complex process, relying heavily on the expertise of skilled technicians. The introduction of laser-based shaft alignment tool kits revolutionized the field, making the process significantly faster, easier, and more accurate. This precision ensures optimal machinery performance and reduces the risk of costly breakdowns.

A basic understanding of the concepts related to shaft alignment is essential. "Offset" refers to the parallel displacement of the shafts, while "angularity" refers to the angle between them. A shaft alignment tool kit measures both offset and angularity to determine the precise adjustments needed.

Using a shaft alignment tool kit offers several key benefits. Firstly, it minimizes vibration, which reduces wear and tear on machine components, extending their lifespan. Secondly, it improves energy efficiency by reducing friction and energy loss. Lastly, it minimizes downtime by preventing unexpected breakdowns.

A successful shaft alignment project involves several steps. First, gather the necessary tools and equipment. Next, prepare the machinery by cleaning the shafts and ensuring they are properly secured. Then, mount the laser transmitters and receivers, following the manufacturer's instructions. Finally, take measurements and make the necessary adjustments until the desired alignment is achieved. A case study involving a large pump demonstrated a 70% reduction in vibration after implementing precise shaft alignment using a laser alignment tool kit.

Advantages and Disadvantages of Shaft Alignment Tool Kits

| Advantages | Disadvantages |

|---|---|

| Increased machine lifespan | Initial investment cost |

| Reduced energy consumption | Requires training to operate effectively |

| Minimized downtime | Can be sensitive to environmental factors |

Best Practices for Implementing Shaft Alignment Tool Kits:

1. Ensure proper training for personnel using the equipment.

2. Regularly calibrate the alignment tools to maintain accuracy.

3. Follow the manufacturer's instructions carefully.

4. Document alignment procedures and results.

5. Establish a preventative maintenance schedule for shaft alignment.

FAQs:

1. What is shaft alignment? Answer: Shaft alignment is the process of ensuring that rotating shafts are precisely aligned.

2. Why is shaft alignment important? Answer: Proper shaft alignment minimizes vibration, extends machine life, and reduces energy consumption.

3. What are the different types of shaft alignment tools? Answer: Common types include laser alignment systems and dial indicator methods.

4. How often should shaft alignment be performed? Answer: The frequency depends on the specific machinery and operating conditions.

5. What are the signs of misalignment? Answer: Excessive vibration, noise, and heat are common indicators.

6. What is the cost of a shaft alignment tool kit? Answer: Prices vary depending on features and capabilities.

7. How can I choose the right shaft alignment tool kit? Answer: Consider factors such as accuracy, ease of use, and application requirements.

8. Where can I find training on shaft alignment? Answer: Many manufacturers and training organizations offer courses on shaft alignment.

Tips and tricks for using a shaft alignment tool kit include ensuring a stable mounting surface for the equipment, using proper measurement techniques, and taking environmental factors such as temperature into consideration.

In conclusion, investing in and properly utilizing a shaft alignment tool kit is crucial for maintaining the health and efficiency of rotating machinery. By ensuring precise alignment, you can significantly reduce vibration, extend equipment lifespan, minimize energy consumption, and avoid costly downtime. The various types of shaft alignment tool kits available cater to diverse needs and applications. Understanding the principles of shaft alignment, following best practices, and addressing potential challenges will empower you to optimize your machinery's performance and achieve long-term cost savings. Take the proactive step of implementing a comprehensive shaft alignment program today to reap the rewards of enhanced productivity and reduced maintenance expenses. Don't wait for a costly breakdown to realize the importance of precise shaft alignment – make it a priority now.

Hacking conflict resolution pre institution mediation rules decoded

The cast iron egg whisperer mastering the art of sizzling perfection

Transform your space with behrs polar bear white a comprehensive guide