Mastering Grade 8 Bolt Torque: A Comprehensive Guide

Are you working on a project that requires high-strength fasteners? Chances are you'll be encountering grade 8 bolts. These robust fasteners are a mainstay in demanding applications, but their strength is only fully realized when tightened to the correct torque. Understanding and applying the right torque values for grade 8 bolts is essential for achieving a secure and long-lasting connection.

Torque values for grade 8 bolts are not arbitrary numbers; they are carefully calculated specifications designed to maximize the clamping force and prevent failure. Incorrect tightening can lead to a variety of problems, from stripped threads and broken bolts to joint loosening and ultimately, structural failure. This guide will delve deep into the world of grade 8 bolt torque, providing you with the knowledge and resources you need to ensure your projects are built to last.

Grade 8 bolts, recognized by their six radial lines on the head, are made from medium carbon alloy steel, quenched and tempered for exceptional strength and durability. They are commonly used in automotive, construction, and industrial applications where high tensile strength and fatigue resistance are paramount. The history of standardized bolt grading systems goes back to the early 20th century, driven by the need for consistent quality and performance in engineering applications. These standards have evolved over time, reflecting advancements in materials science and engineering practices.

One of the main issues related to achieving the proper tightening of grade 8 bolts is the variability of friction. Factors like surface finish, lubrication, and even the presence of debris can significantly influence the relationship between applied torque and the resulting clamping force. This is why relying solely on "feel" or guesswork is insufficient. Accurate torque wrenches and proper lubrication are essential tools for achieving consistent and reliable results.

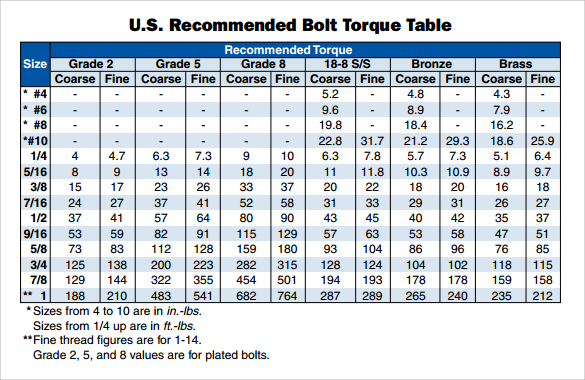

Torque is defined as a rotational force applied to a fastener. It is measured in units like foot-pounds (ft-lbs) or Newton-meters (Nm). The torque value for a grade 8 bolt represents the optimal rotational force required to achieve the desired clamping force without over-tightening. For example, a common torque specification for a 1/2" grade 8 bolt might be around 75 ft-lbs, but it's always crucial to consult the manufacturer's specifications or relevant engineering standards for the specific application.

One benefit of using correct grade 8 bolt torque values is enhanced safety. Properly tightened bolts ensure structural integrity, preventing catastrophic failures that could lead to injury or property damage. Another advantage is increased reliability. Accurate torque application minimizes the risk of joint loosening over time, reducing maintenance costs and downtime. Lastly, proper torque contributes to the longevity of the bolted connection. By avoiding over-tightening, you prevent stress concentrations and fatigue failure, extending the lifespan of the components.

A simple action plan for ensuring correct torque involves using a calibrated torque wrench, applying the correct lubricant, and consulting the appropriate torque specifications. Start by cleaning the bolt and nut threads. Then, apply the specified lubricant. Finally, using a calibrated torque wrench, tighten the bolt to the manufacturer's recommended torque value.

Checklist for tightening grade 8 bolts:

1. Identify the correct grade and size of the bolt.

2. Consult the manufacturer's specifications for the recommended torque value.

3. Clean the bolt and nut threads.

4. Apply the appropriate lubricant.

5. Use a calibrated torque wrench.

6. Tighten the bolt in a slow and controlled manner.

Advantages and Disadvantages of Grade 8 Bolts

| Advantages | Disadvantages |

|---|---|

| High Strength | Higher Cost |

| Durability | Can be brittle |

| Fatigue Resistance | Require specific torque procedures |

Best Practices:

1. Always use a calibrated torque wrench.

2. Lubricate threads properly.

3. Tighten in a controlled manner.

4. Consult manufacturer specifications.

5. Inspect bolts regularly.

Real Examples:

1. Automotive engine assembly

2. Structural steel connections

3. Heavy machinery assembly

4. Bridge construction

5. High-pressure piping systems

Challenges and Solutions:

1. Over-torquing: Use a calibrated torque wrench

2. Under-torquing: Follow torque specifications

3. Thread damage: Clean threads before assembly

4. Bolt breakage: Ensure proper bolt selection

5. Galvanic corrosion: Use compatible materials

FAQ:

1. What is the torque value for a 1/2" grade 8 bolt? (Consult manufacturer specifications)

2. How do I calibrate a torque wrench? (Refer to the wrench's instructions)

3. What lubricant should I use? (Consult manufacturer specifications)

4. What is the difference between grade 5 and grade 8 bolts? (Grade 8 has higher strength)

5. Can I reuse a grade 8 bolt? (It depends on the application)

6. How do I prevent over-torquing? (Use a calibrated torque wrench)

7. What are the signs of a loose bolt? (Movement, noise, vibration)

8. Where can I find torque specifications? (Manufacturer's documentation)

Tips and Tricks:

Always double-check your torque specifications. When in doubt, err on the side of caution and slightly under-torque rather than over-torque.

In conclusion, understanding and applying the correct torque values for grade 8 bolts is paramount for ensuring the safety, reliability, and longevity of your projects. From automotive applications to structural engineering, these high-strength fasteners play a vital role in countless critical applications. By following the guidelines and best practices outlined in this guide, you can maximize the performance of your grade 8 bolts and prevent costly failures. Remember to always consult manufacturer specifications and utilize calibrated tools. Taking the time to master these principles will pay dividends in the long run, ensuring your projects are built to stand the test of time. Properly torqued grade 8 bolts provide a strong foundation for any project, ensuring that your hard work is secure and dependable. Invest in the right tools, follow best practices, and consult reliable resources to ensure your projects are built with confidence. This will not only enhance the quality of your work but also contribute to your reputation as a skilled and knowledgeable professional.

Unlocking apple pay with visa gift cards a comprehensive guide

Navigating the complexities of grey zone warfare

Va disability payments your guide to payment schedules