Drive Axle Nut Torque Specs: A Crucial Element of Wheel-End Integrity

Ever wondered what keeps your wheels securely attached to your vehicle? It's more than just bolts and nuts; it's precision engineering, and a critical part of that is understanding drive axle nut torque specifications. These specifications, often overlooked, play a crucial role in ensuring the safety and longevity of your vehicle.

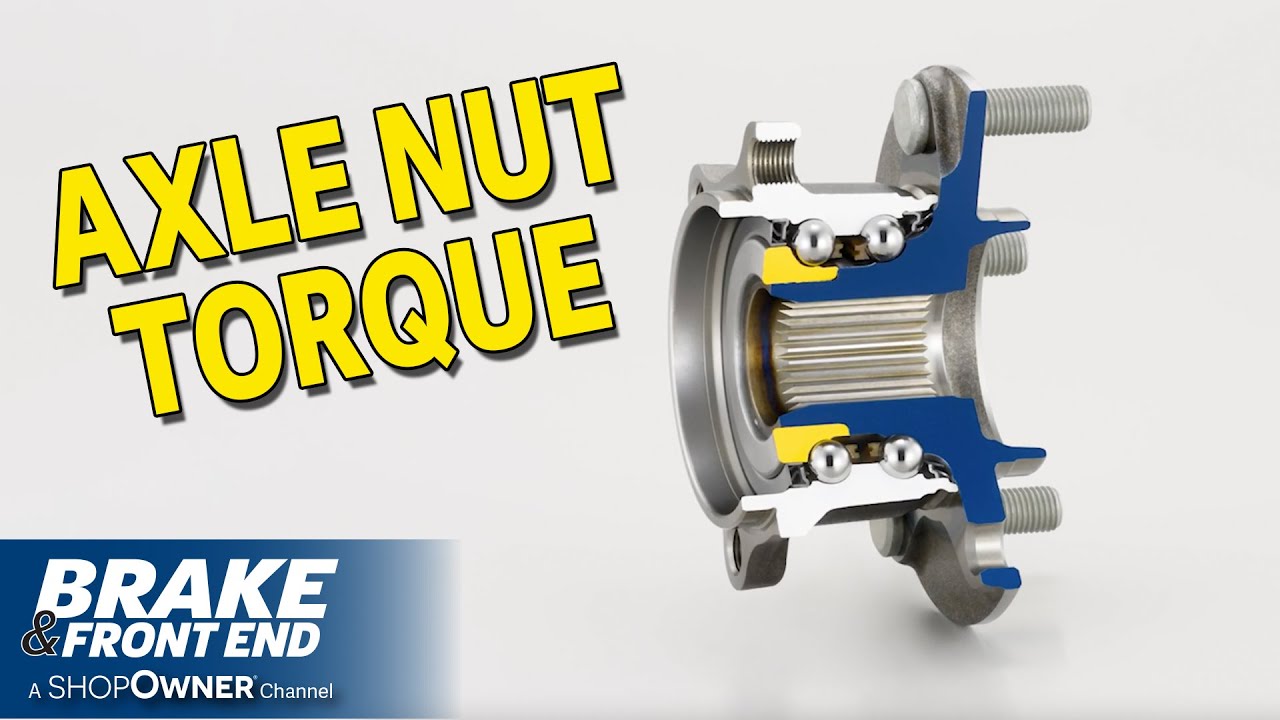

Drive axle nut torque, simply put, refers to the precise amount of rotational force required to tighten the nut that secures the drive axle or hub to the vehicle. Getting this right is paramount for preventing wheel detachment, bearing failure, and a host of other potentially dangerous and costly issues. Ignoring these specifications can lead to a compromised wheel assembly, putting you and others at risk.

The history of drive axle nut torque specs is intertwined with the evolution of automotive engineering. As vehicles became more complex and performance-driven, the need for precise fastening methods became increasingly important. Early automobiles relied on simpler designs, but with the advent of higher speeds and heavier loads, standardized torque specifications became essential. This evolution reflects the ongoing pursuit of safety and reliability in the automotive industry.

The importance of adhering to the correct drive axle nut tightening values cannot be overstated. Properly torqued nuts ensure that the wheel bearing preload is within the manufacturer's recommended range. This optimal preload minimizes wear and tear, extends bearing life, and promotes smooth operation. Conversely, incorrect torque can lead to premature bearing failure, excessive vibration, and even wheel separation, posing a significant safety hazard.

One of the main issues related to drive axle nut torque specs is the variation between different vehicle makes and models. There is no one-size-fits-all torque value. Each vehicle has specific requirements based on its design, weight, and intended use. Consulting the vehicle's service manual is crucial for obtaining the correct specifications. Using incorrect torque, even if it seems "close enough," can have detrimental effects.

A drive axle nut torque specification is expressed in units of force multiplied by distance, typically foot-pounds (ft-lbs) or Newton-meters (Nm). This value represents the precise rotational force that should be applied to the nut during tightening. For instance, a specification of 150 ft-lbs means that 150 pounds of force should be applied to a lever one foot long to tighten the nut. Using a torque wrench is essential for achieving this precise measurement.

One benefit of adhering to proper axle nut torque is improved safety. Correctly tightened nuts prevent wheel detachment, a dangerous scenario that can lead to loss of control and accidents. Another benefit is extended bearing life. Proper torque ensures optimal bearing preload, reducing friction and wear, leading to longer bearing life and less frequent replacements. Finally, proper torque contributes to better fuel efficiency. Reduced friction in the wheel bearings translates to less energy wasted, leading to slightly improved fuel economy.

To ensure you are applying the correct drive axle nut torque, always consult your vehicle's service manual. This manual provides the specific torque specifications for your vehicle's make and model. Acquire a calibrated torque wrench. Using a regular wrench won't provide the necessary precision. Follow the tightening sequence outlined in the service manual. This sequence ensures even pressure distribution and proper seating of the nut. After driving a short distance, re-torque the nuts to ensure they remain properly secured.

Advantages and Disadvantages of Precise Drive Axle Nut Torque

| Advantages | Disadvantages |

|---|---|

| Enhanced Safety | Requires Specialized Tools (Torque Wrench) |

| Increased Bearing Life | Time-Consuming if not familiar with the process |

| Improved Fuel Efficiency | Potential for damage if incorrect torque is applied |

Best practices include cleaning the threads of the axle and nut before installation, lubricating the threads as specified in the service manual, using a calibrated torque wrench, following the recommended tightening sequence, and re-torquing the nuts after a short drive. Real-world examples include tightening the axle nuts on a heavy-duty truck, securing the wheel hub on a passenger car, and installing the drive axle on an off-road vehicle. Each application requires specific torque values to ensure proper operation and safety.

One challenge is over-tightening, which can damage the threads or the bearing. The solution is to use a calibrated torque wrench and follow the manufacturer's specifications. Another challenge is under-tightening, which can lead to wheel detachment. The solution is to re-torque the nuts after a short drive. A third challenge is using the wrong torque specification. The solution is always to consult the vehicle's service manual.

FAQs include: What is drive axle nut torque? Why is it important? What are the consequences of incorrect torque? What tools are needed? Where can I find the specifications for my vehicle? How often should I check the torque? What should I do if I over-tighten the nut? How can I prevent problems related to axle nut torque?

A helpful tip is to mark the nut and axle with a paint pen after tightening to easily visually inspect for any loosening.

In conclusion, understanding and adhering to drive axle nut torque specifications is paramount for vehicle safety, performance, and longevity. From preventing catastrophic wheel detachment to extending the life of crucial components, proper torque plays a vital role. While seemingly a small detail, the correct application of torque contributes significantly to the overall reliability and safety of your vehicle. Don't underestimate the importance of this often overlooked aspect of vehicle maintenance. Invest in a quality torque wrench, consult your vehicle's service manual, and follow the recommended procedures. Taking the time to properly torque your drive axle nuts is a small investment that pays off big in terms of safety, performance, and peace of mind. By understanding the principles behind drive axle nut torque and implementing the best practices outlined above, you can ensure a smoother, safer, and more enjoyable driving experience. Make it a part of your regular maintenance routine, and your vehicle will thank you for it.

Driftwood motel point pleasant nj retro beach vibes

Audi rs5 laptop wallpaper pimp your screen

Navigating the gs special pay scale for it professionals